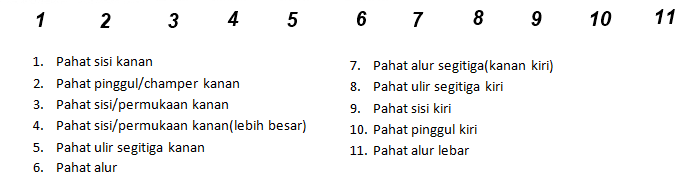

Lathes A lathe is a machine that has the working principle of turning the workpiece, then cutting it using a lathe. Chisel lathe is a very important component in the turning process. This lathe chisel is used as a cutting tool to cut the workpiece to form what is desired. There are many types of lathe chisels that have their respective functions or uses.

The following types are based on their classification.

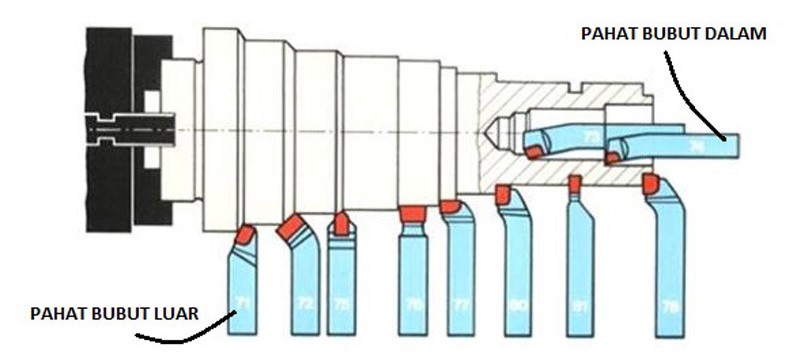

Lathe Chisel Based on the Location of the Sticking

- Outer Lathe Chisel

This chisel is used for the process of turning the outer surface of the workpiece

- Inner Lathe Chisel

While the inner lathe chisel is used for deep turning of the workpiece.

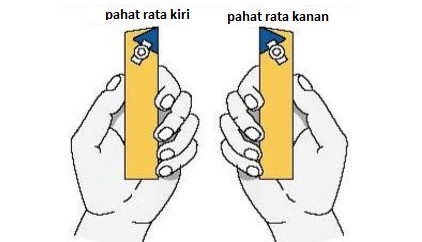

Lathe Chisel Based on the Position of The Cut Eye

- Right Flat Chisel Left

flat chisel is a type of lathe chisel where the position of the cutting eye is on the left, when the chisel is faced towards us. And the turning direction is from left to right.

- Right Flat Chisel Right

flat chisel is a type of lathe chisel whose cutting eye is on the right side when the chisel is faced towards us. And the turning direction is from right to left.

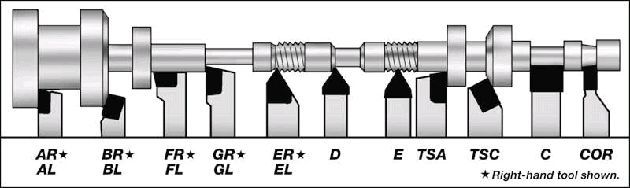

Lathe Chisel Based on This Function

- Flat lathe chisel

Flat chisels are used for the process of longitudinal turning with an even result.

- Facing lathe chisel

The facing chisel is used for the process of transverse turning on the surface of the end of the workpiece.

- cutting lathe chisel

Chisel used for cutting the workpiece. This chisel is flattened and strong

- Groove lathe chisel

Chisel used for the profiling process or workflow of the workpiece

- Threaded lathe chisel

Chisels used to make threads, both inner threads and outer threads.

- Chamfer lathe chisel

Chisel used to create a champer or angle of inclination at the end of the workpiece.

- Cartel lathe chisel

Chisels used to carcarce or make rough serrations on the surface of the workpiece

- Chisel lathe drilling

Chisels used to make holes or drill workpieces

The conclusion is that before we carry out the turning process, we must be able to choose which tool we are going to use. And also have to make sure of the condition of the chisel whether it is still suitable for use or not. Because the condition of the tool greatly affects the texture of the workpiece as a result of the turning process.

Written by Qoimam Bilqisthi

Student of Sebelas Maret University (UNS) Surakarta, Mechanical Engineering Education Study Program Class of 2020

READ ALSO: Get to Know Various Measuring Instruments in Machining Techniques