A wheelchair is an essential tool for those who rely on assistive devices for daily mobility. The UN Convention on the Rights of Persons with Disabilities (CRPD) recognizes that independent mobility is a human right, and people with disabilities have the right to demand appropriate wheelchairs. In Indonesia, there are 11 million people with disabilities, or around 4.5 percent of the population. Sports wheelchairs have an important role in supporting the mobility and health of their users. To improve their quality of life, ergonomic design is the main key. One of the latest approaches adopted in the manufacture of sports wheelchairs is the use of anthropometric measurements.

The Effect of Sports Wheelchairs on Athletes’ Movement Ability

In the world of wheelchair sports such as basketball, rugby, and tennis, many important changes have occurred over the years. Progress in athlete performance becomes more developed thanks to good physical condition, increased technical ability and understanding of strategy. In addition, this sports wheelchair has experienced increasing feature development. A designer must ensure that the wheelchair not only makes things easier for athletes but also creates a feeling of comfort when they are on the field.

To improve the performance and comfort of athletes in this sport, harmonization of ergonomic sports wheelchair design with anthropometric measurements is the key to achieving optimal harmony between the equipment and an athlete’s physical characteristics. Below we will discuss the role of anthropometric measurements in the wheelchair design process.

The Role of Anthropometrics in the Wheelchair Design Process

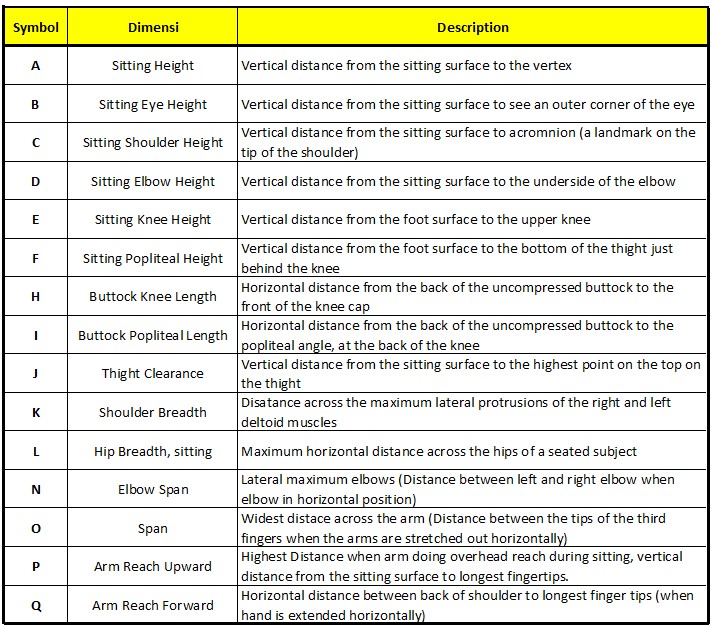

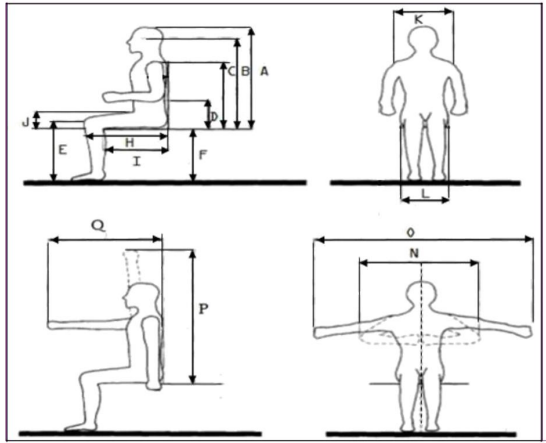

The success and comfort of a wheelchair user depend not only on its design but also on careful anthropometric measurements. The process of designing an ergonomic sports wheelchair requires important anthropometric measurement steps. According to a journal written by Jarosz (1996), seventeen anthropometric dimensions are measured when the subject sits with the thigh parallel to the surface and the knee bent 90 degrees. The choice of anthropometric body dimensions is considered according to their significance and use.

Wheelchair designs that provide comfort for users need to pay attention to the anthropometric measurement process. Anthropometric measurements are carried out using equipment that has professional anthropometer standards, such as: a stadiometer, sliding caliper, spreading caliper and measuring tape. The following are the anthropometric dimensions needed to design a wheelchair.

Over the past few years, there has been a significant evolution in the design and configuration of sports seats. Athletes now have a wide variety of options to customize wheelchairs according to their preferences and needs. By taking these anthropometric measurements into account, sports wheelchair designs can be optimized to provide a suitable and comfortable experience for users.

Anthropometric Measuring Instruments that Have Professional Standards

Metrisis – Portable Anthropometry made by Solo Abadi Indonesia is a body measurement tool that comes from an anthropometric chair. This tool is designed to be easy to carry and move anytime and anywhere. Like other innovations, this portable anthropometric measuring tool can measure more than 100 dimensions of the human body. Currently, many universities in Indonesia use Portable Anthropometry Kits. The following are the Anthropometric Potable Kit product details:

The function of Metrisis is to carry out anthropometric measurements which are carried out carefully and prioritize the accuracy of the data obtained. This tool can take up to 100 different measurements. The portable form is one of the advantages of this tool, making it easier for users without time and place restrictions, it can be used anywhere.

Get the Portable Anthropometry Kit from Solo Abadi immediately by filling in the ask for price column provided. You can also contact us directly via WhatsApp because we are ready to contact you immediately.

This article was written by Veronica Putri Ning Nugraha, a student of the Polytechnic ATMI Surakarta, in the Manufacturing Design Study Program.