Here’s a complete guide to CNC G-Code for you, a beginner in machine engineering. G-code is a compilation of commands to control movement, speed, and cutting direction. To understand it, we provide a complete table of G-codes for CNC machines that can assist you!

What is G-Code Blocks?

G Code Blocks represent a series of commands in the G-code language aimed at executing specific functions. In CNC machine programming, these sequences are organized sequentially. Subsequently, the CNC machine reads this program sequentially and executes the commands in the G Blocks.

Also Read: 8 Types of CNC Machines You Need to Learn About

G-code Blocks are recognized by individuals as fundamental elements. Here’s an example of G-code Blocks:

G01 X1 Y1 F20 T01 M03 S500

This single line of function sequence provides a series of instructions to the machine:

- G01: Perform Linear Feed Movement

- X1/Y1: Move from X and Y Coordinates

- F20: Move at Speed 20

- T01: Use Tool 1 for Work

- M03: Turn on the Spindle

- S500: Set Spindle Speed to 500

Read More : The Definition Of CNC Machines And Use Of CNC Machines In The Industrial World

Using G-Code in CNC Machines

The primary purpose of utilizing the G-code programming language is to produce workpieces as efficiently as possible. Typically, CNC Machine operators follow a series of steps:

- Start the CNC Program

- Select the required tool

- Turn on the spindle

- Turn on the coolant

- Move to a position above the workpiece

- Start the machining process

- Turn off the coolant flow

- Turn off the spindle

- End the CNC program

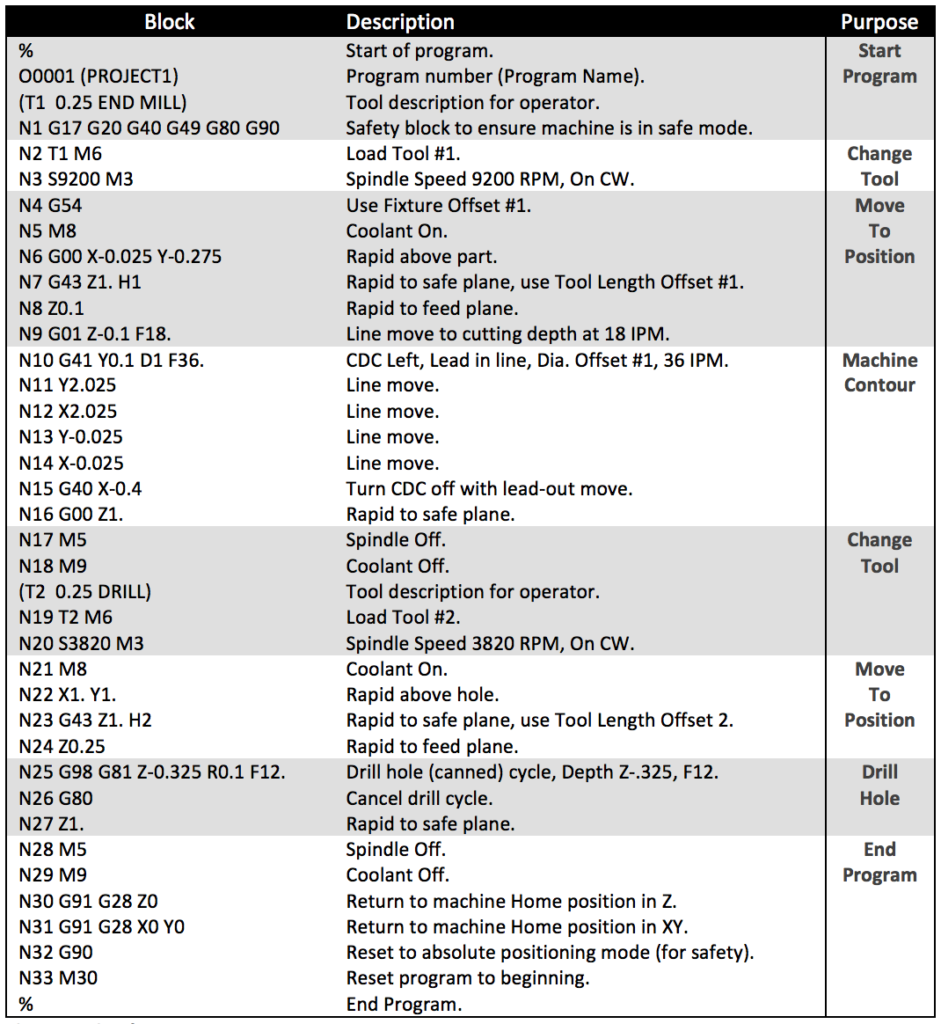

This flow is a simple sequence commonly adopted by CNC operators and repeats steps 2 to 9. Additionally, to repeat movements on your spindle, you only need to use M03 to turn on the spindle and M05 to turn off the spindle. As an example, in the following block:

CNC G-Code for Beginner

Trough time CNC is evolving but the G-Code CNC Brief is the fundamental thing you need to know. Hence, we write it down for you :

| G0 – Rapid Move | Move the machine axes one by one at the specified coordinates |

| G1 – Straight L | Move in a straight line to a coordinate position at a predetermined speed. For example : G1 X1 Y1 F32. This means that the machine will move straight at coordinates X1 to Y1 with speed of 32. |

| G2. G3 | Clockwise and counterclockwise arcs |

| G17, G18, G19 | Indicating which surface will be used to process the arc. |

| G40, G41, G42 | Define cutting tool diameter compensation |

| G43 | Tool length compensation using Z-Axis Height |

| G54 | Defines a device offset that determines the distance from coordinates |

Using CNC Machines to Make Medical Equipment at PT Solo Abadi Indonesia

PT Solo Abadi Indonesia makes medical equipment, like tools for measuring people. They use CNC machines to help make some of the parts. This makes it easier to design new things and makes sure the parts are made really well.

PT Solo Abadi Indonesia is also open to collaboration in the production of precision parts. Contact our admin through WhatsApp or the following link .