Previously, we often provided information about the feeder machine, such as the functions, and uses of the feeder machine. However, this time, we will take a case study regarding the use of feeder machines in industries in Indonesia. The feeder itself is currently known as an automatic feeder machine or a friction feeder.

Although the use of feeder machines is essential for the industrial world. However, the feeder is still a machine whose functions and uses are not yet known.

In fact, did you know that the feeder machine is very important to use in the packaging field. Let’s discuss with us about this.

Packaging Process of Goods

Next, we can discuss about, what is the packaging process in an item? Packaging is a way to protect products and facilitate marketing and distribution to manufacturers, distributors, and consumers.

In addition, packaging combines art, design, and technology to wrap, cover, or protect a product so that the product is not damaged during the distribution process.

Some of the industries that actively carry out product packaging are as follows:

- Pharmaceutical industry

- Health Industry

- Food and Beverage Industry

- Cosmetics and Beauty Industry

- Retail Industry

- And so forth.

Packaging is the last step but has a primary function. Because good packaging certainly increases the selling value and satisfaction of the customer or client. For this reason, the packaging is an important part of the production of goods.

In the process of packaging goods, we usually go through several processes, for example, the process of printing packaging labels, the process of printing ordinary paper to the process of entering the product into the packaging.

This is where the feeder machine has a big enough contribution. Why is that? Feeder machines help to increase productivity at the time of packaging. For example, as in the packaging labeling process, with a feeder machine, labeling can be done more quickly.

Because the feeder machine collects the packaging paper, then releases it one by one to the conveyor. Which is then further processed at the time of printing packaging.

The Importance of Feeder Machine in The Packaging Process of Goods

The feeder machine is an important part because it helps the process of packing goods. The workings of the feeder machine are to collect the paper packaging paper and remove the packaging paper and flow the paper through the conveyor.

After that, the next process that can be done is to do product printing or product labeling. Some of the advantages of using a Light Feeder Machine for the packaging process are as follows:

- Helping the packing process more efficiently

- Can be applied with other machines so that packing is faster

- It doesn’t take up much space because of the minimalist shape

- Can be used for various sizes

- It is adjustable for all needs

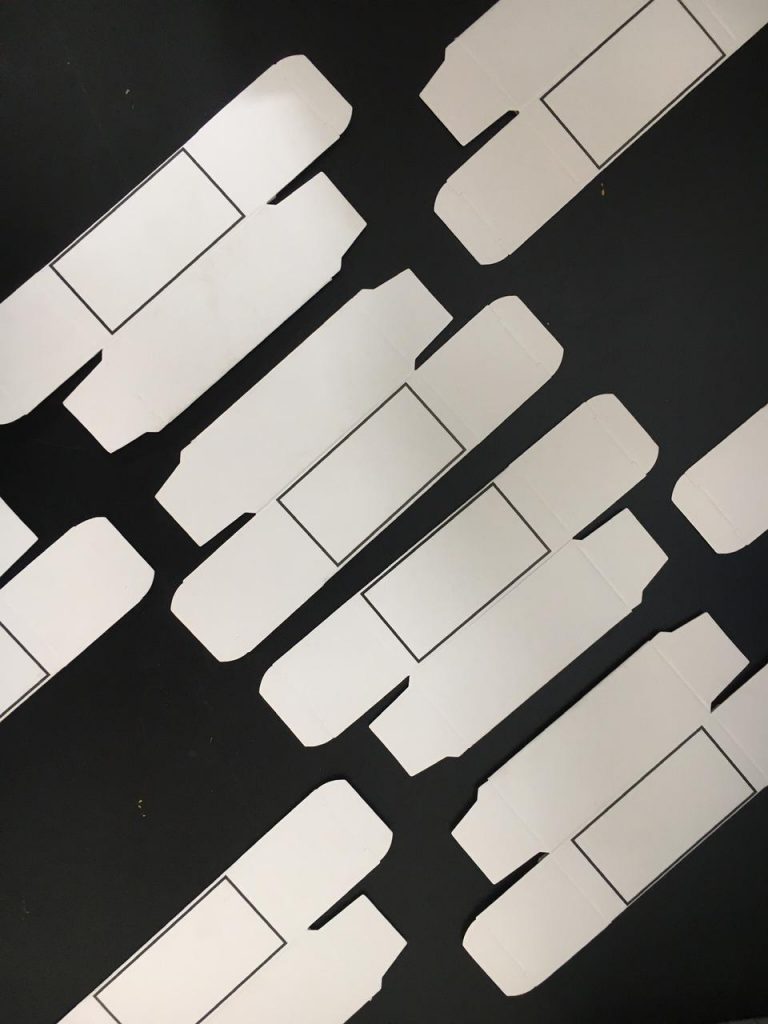

The following is an example of packaging for cosmetic packaging made of paper before printing:

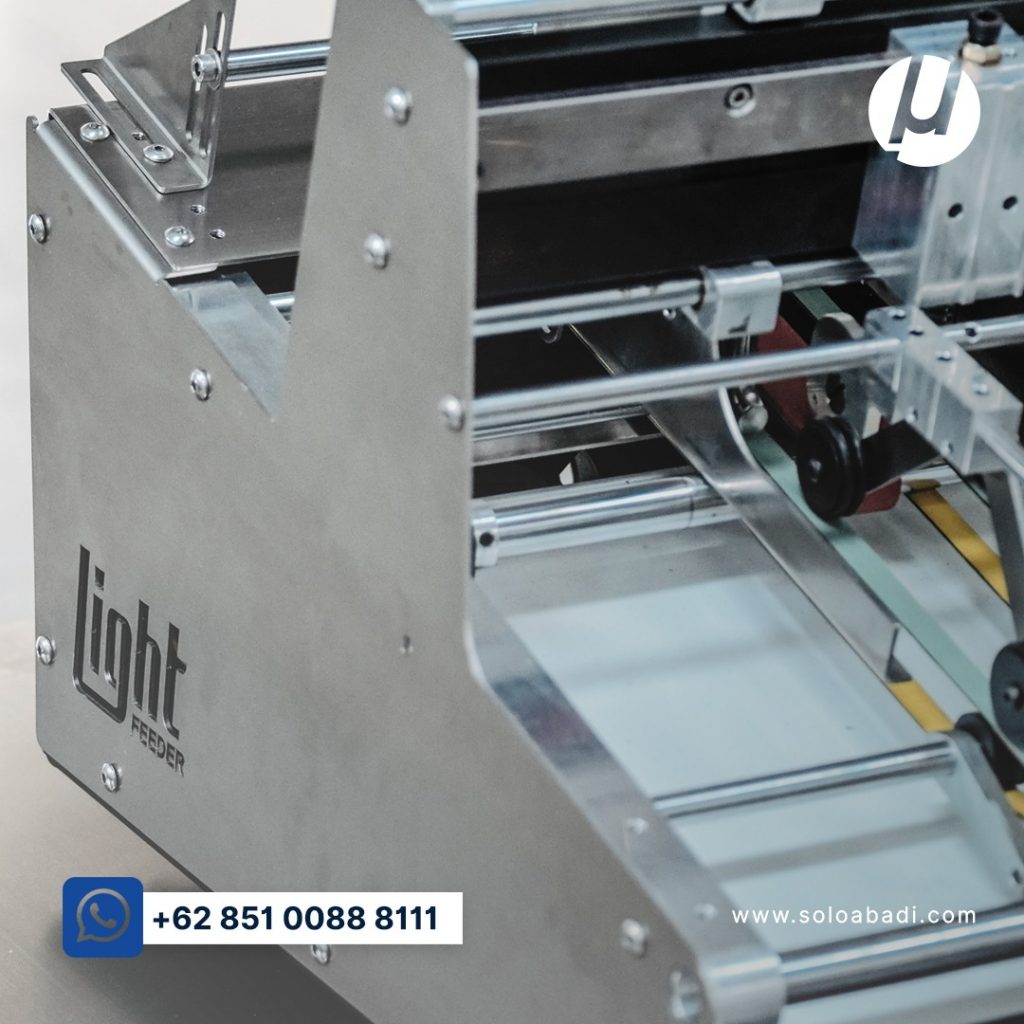

Trial of light feeder machine for Cosmetic Packaging:

Light Feeder Machine from Solo Abadi Indonesia

light Feeder Machine is a feeder used to remove paper one by one in the feeder, which is then flowed using a conveyor. The light feeder itself is the only feeder machine in Indonesia. Some of the advantages of our Feeder Machine are as follows:

- Automatic Feeder Device System

- Simple and Easy to operate.

- Feeder speed can be adjusted.

- Product size can be adjusted to your needs.

- Can integrated to other machines such as labelling machines, folding, injection printing.

- Easy to clean and use for a long period.

- Made of Stainless Steel so that the machine is anti-rust and stronger

In addition, our machines have been used in various industries, one of which is the cigarette and printing industry. If you need a feeder machine to maximize the production process, one of them is for the packaging process. Light Feeder can be your best choice and solution machine.

Get It Immediately and Consult Light Feeder Machine from Solo Abadi Indonesia

Get the best Light Feeder Machine offer from Solo Abadi Indonesia by ASK FOR PRICE or contact us via our contact at 62-851-0088-8111 which is beside, please contact us via WhatsApp for a FREE consultation with us.

You can also request a product trial to us. Please contact us directly now. We are ready to serve you.