Have we ever imagined about how the current production system works. For example, if you look at all the conditions around us. How does transportation move. In addition, if we look around us there are so many things that using technology with complicated part. Such as for cars or motorcycles, planes, trains, etc. Have you ever imagined how many components are used in one vehicle? How many thousands of parts must be combined to make a vehicle run properly and in accordance? Many of these tools also use parts that are important and essential. How many machine parts or parts can support our lives?

The Importance of Precision Part

Precision can be interpreted as quality, condition of the item, or the fact that it is precise and accurate, or in short precision is the most important thing. Precision in a part is one of the keys to success in producing an ergonomic product or work that is used by most consumers.

The importance of accuracy in producing a part becomes a benchmark that will determine whether the tool is suitable and able to create maximum use advantage.

In the mining industry, the shipping industry, the automotive industry, and other manufacturing industries, no matter how small the parts needed, if the parts do not have the right precision. Then the use and value of the goods will be disrupted.

Precision Part as an Important Component in the Manufacturing World

In the manufacturing industry, the accuracy of a product is very important. Each and every product has its own dimensions and sizes that must be adjusted. Where even a product is considered defective or rejects, even though there was only a mistake of 0.1 percent of the design in the product.

Every industry must maintain its standards by providing accurate products with perfect precision. Well, it is seen from the dimensions of size, shape, and threading in a product. Both in terms of large and small devices, accuracy or precision is very important. Precision can be made in several ways, but mainly by looking at how the competence of a company or factory to create precision tools. In addition, the production equipment determines a product that can be produced with perfect precision.

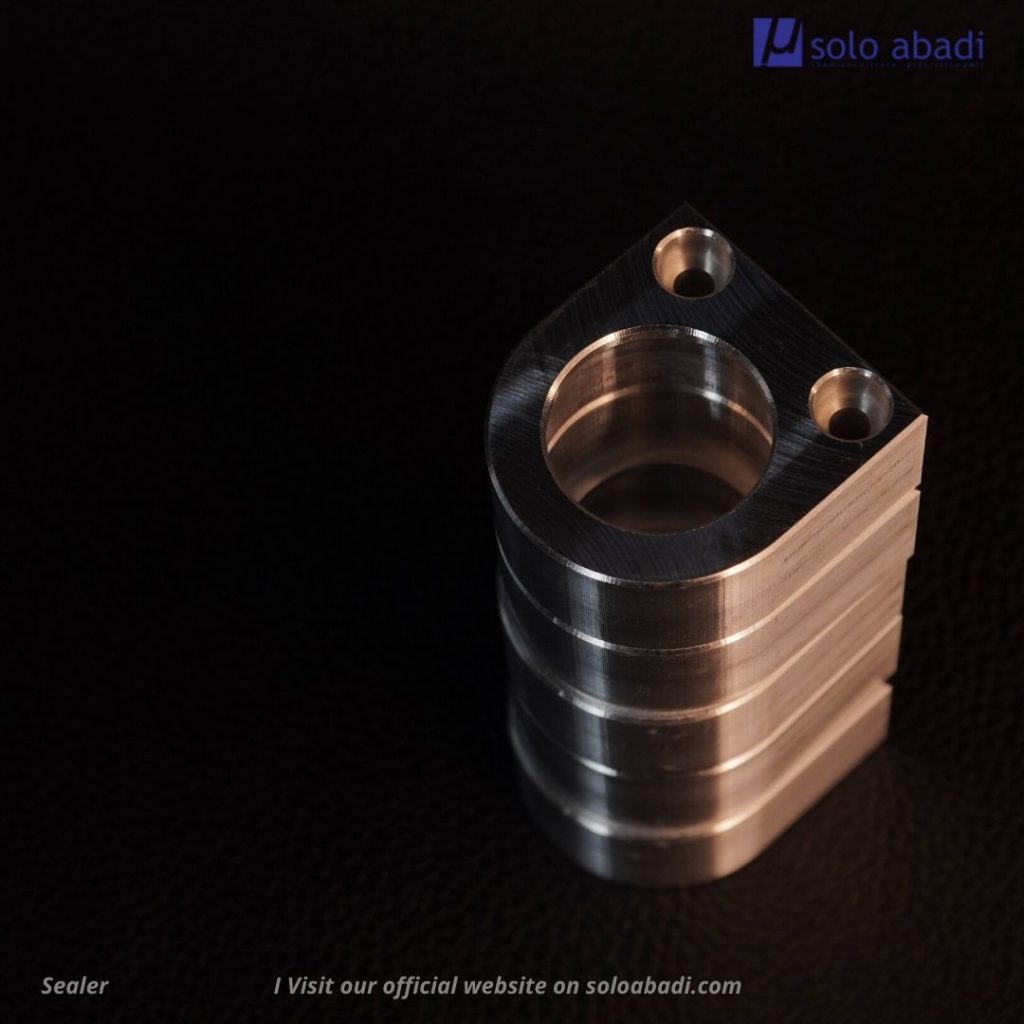

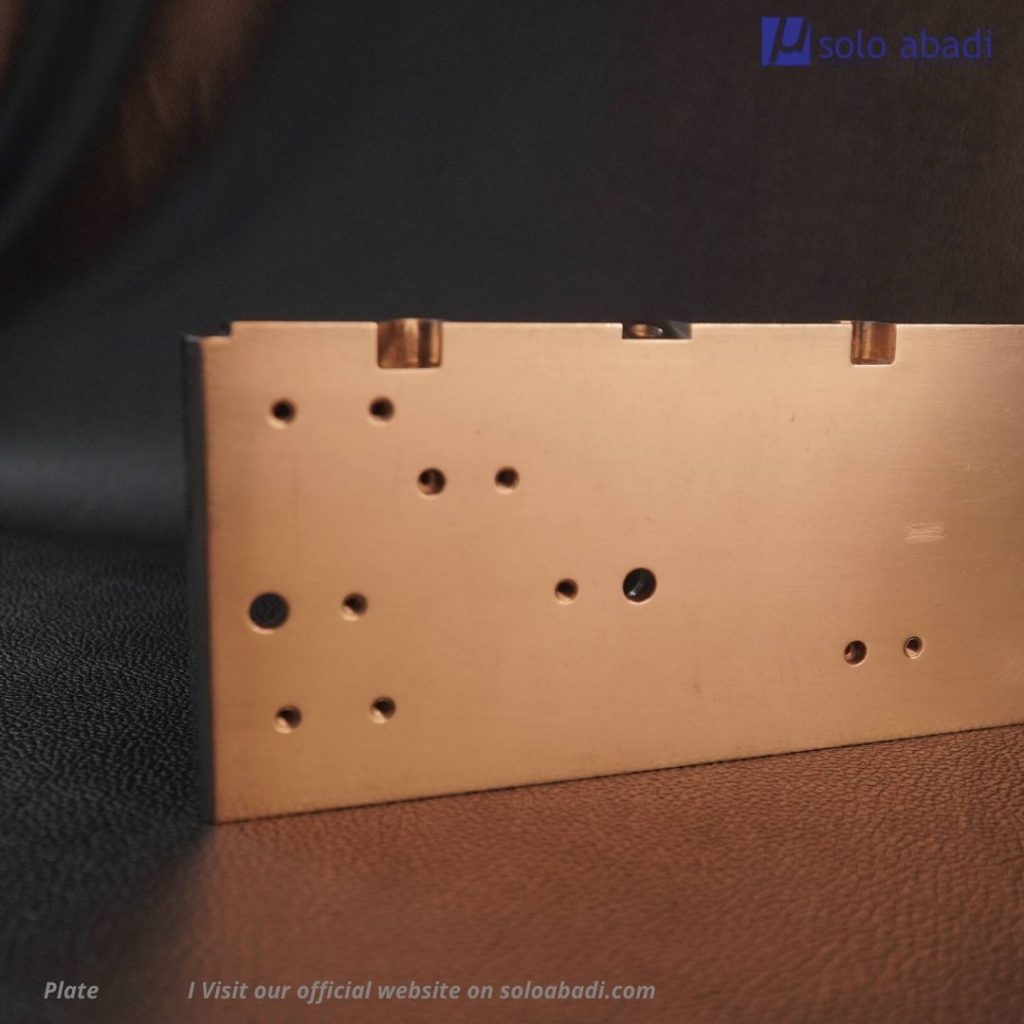

Here are some precision parts produced by SOLO ABADI:

Why Use CNC in Precision Part Production

CNC machining is one of the keys to making the production of appropriate precision parts. CNC can be used to produce goods with a high degree of accuracy, both in goods with small and large dimensions.

Every manufacturing company strives to develop efficiency in the product. And by using CNC technology, this can be done most easily. Although of course, accuracy, the competence of employees, and experience remain the key to success in creating the right precision parts.

But by using CNC Machining, the company can fulfil all the choices of its clients with a process that only requires a little human intervention. To produce high-quality parts that can be produced frequently.

Choosing a Trusted Expert to Produce Quality Precision Parts

Seeing how important a precision is in working on a part. So, it is important to choose a company or factory with proven expertise and focus on quality and accuracy.

SOLO ABADI as a manufacturing company that has experienced for more than 15 years working in the industrial world. Able to meet market needs for precision parts needed. We are experts in precision parts that are used in various industrial fields such as:

- Manufacture

- Shipping Industry

- Aviation Industry

- Mining Industry

- Agriculture Industry

- Automotive Industry

Besides that, we can also produce goods with various types of raw materials such as:

- Aluminium

- Stainless steel

- Copper

- Brass

- Nickel

- Titanium

- Hastelloy

- Inconel

- Molybdenum

The combination of knowledge, expertise, and real-world experience in working with these materials enables us to choose the best precision CNC machining option for the part or component you want. So, there is no need to hesitate to create precision parts that suit your needs. SOLO ABADI focuses on making accurate, precise but efficient precision that is expected to be able to benefit each of our clients.

We also have the best design team that can help you to provide relevant information about the options and options you need.

With the latest equipment that we have and our young operators and technicians are highly trained. SOLO ABADI strongly believes that we can create every product, by producing prototypes and then turning to full-scale production according to the needs of our clients throughout Indonesia.

How to contact SOLO ABADI?

If you are sure to collaborate with us, please contact us now through our website, email us at admin@soloabadi.com or through our WhatsApp now. SOLO ABADI has an outstanding track record for managing projects from start to finish to meet all quality standards and meet all deadlines.

Contact SOLO ABADI today to get the precision parts you will need.