Lately, we often discuss few articles or news about several terms that exist in the world or field of the manufacturing industry. Such as a article about the understanding of CNC machines, and about how the importance of a precision component in product and industrial design, and so on.

As you might already know, the process of manufacturing precision products or components from zero to finished can do using a CNC machine. The use of CNC machines in making a product or precision component looks like a professional painter who is painting his work.

By using various brushes, balanced colour proportions to the use of suitable techniques, a painter can create masterpieces that can be considered charming, such as product results or spare parts produced by CNC machines.

Some Misconceptions About CNC Machine

Due to the lack of information obtained or hearing news that is not entirely accurate, many people are still experiencing misunderstandings of CNC machines. To anticipate this, the following are the things that are less precise about CNC machines:

1. Operating a CNC Machine Is Very Easy

By reading some of our recent articles, you must understand that the existence of CNC machines is beneficial in the production process of a precision machine component or a remarkable product. We can produce precision parts on the machine quickly and easily. However, before achieving this, you must have made a program that is under what is needed.

The process before we put the material into a CNC machine is quite time-consuming. Besides, you must try and test the program, whether it is following the product to be made or not. This step must be highly considered if you want to produce quality precision products.

2. The Existence of CNC Machines Taking on Human Work

The existence of CNC machines in industrial 4.0 like this is very reasonable because the sophistication of technology is significant to help all human demands and needs, one of them is in providing precision machined components and unique custom products.

But, does the existence of a CNC machine cause job opportunities for lathe or milling’s workers to decrease? Of course not. Using a CNC machine in producing a product only improves the processing process to be fast; it does not mean that the machine can work automatically. CNC machines still require an operator who can make the program as desired and can monitor the production process to be precise and specific in a short time.

3. Limitations of Products that are provided by CNC Machines

Many assume that complicated parts are challenging to apply using a CNC machine because of the complexity of the program that they need to prepare. In contrast to conventional lathe/milling workers who can make it with experience and instincts that own by them.

Though it is not very appropriate, with advances in technology going crazy over the years, CNC machines can produce precision machined components or custom products with complex geometries. With the results of designs that use applications such as CAD (Computer-Aided Design) software then with CAM (Computer Aided Manufacturing), we can make these products after the design results change into programming languages with the NC (Numerical Control) code.

As described earlier, the existence of CNC machines is very reasonable considering we are now in the industrial phase 4.0. There have been many manufacturing industries that provide manufacturing services for machine parts or outstanding product machines / unique custom products using CNC machines, one of which is SOLO ABADI.

Services for Making Precision Parts and Special Products with CNC Machines

As a manufacturing company established for 15 years, Solo Abadi trust by numerous clients and has produced thousands of engine parts and unique custom products. Here are the various services that you can get:

- Lathe Services;

- Milling Services;

- Fabrication Services;

- Machining Services; and

- Special Product Machine Services.

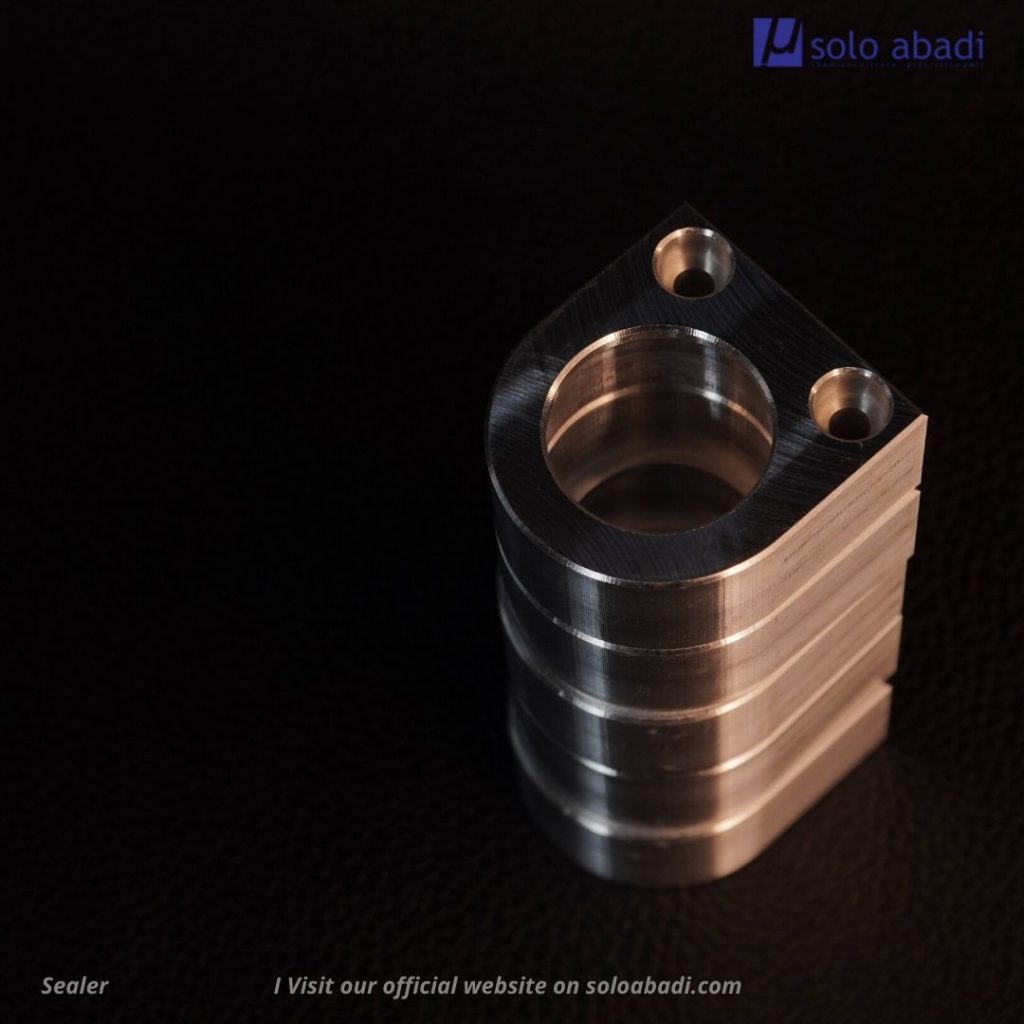

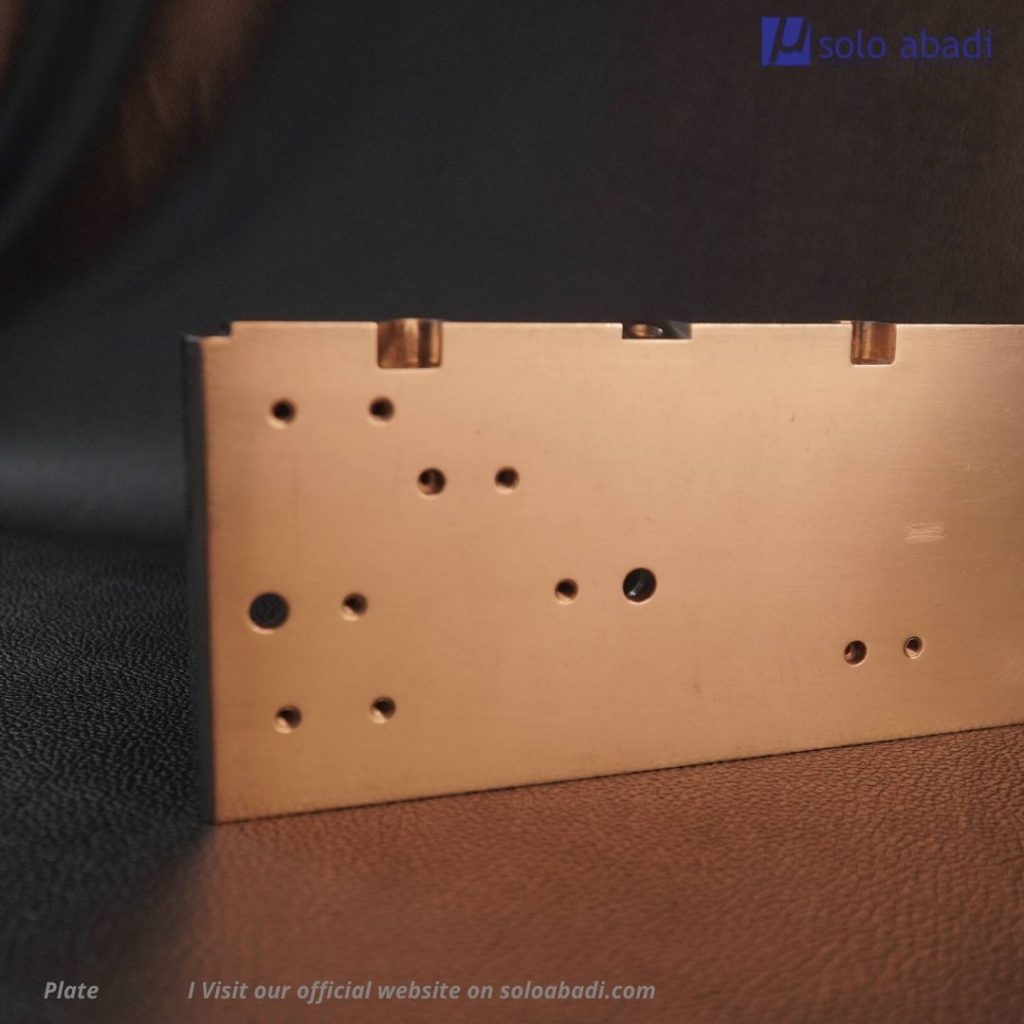

If you are interested in collaborating with Solo Abadi, you can contact us through the following link. You can also contact us through our WhatsApp number. As proof of our professionalism, here are some photos of the components we have produced.