Workplace Ergonomic Safety entails safeguarding workers and company assets from workplace accidents. Therefore, in organizing the warehouse, it is crucial to ensure that the workspace is ergonomic. An ergonomic warehouse, by definition, adheres to safety standards and to accommodate the physical capabilities of its workers. Here are 5 important tips in warehouse work safety that you need to know!

What is Workplace Ergonomic Safety?

It is refers to the practice of designing workspaces, equipment, and tasks to fit the capabilities and limitations of workers. It aims to reduce physical strain and discomfort, prevent injuries, and promote overall well-being in the workplace.

Specially, Warehouse, it is the most busiest area in manufacturing industry. Therefore, creating an ergonomic warehouse is our aim today. First, we need to understand what is ergonomic workplace?

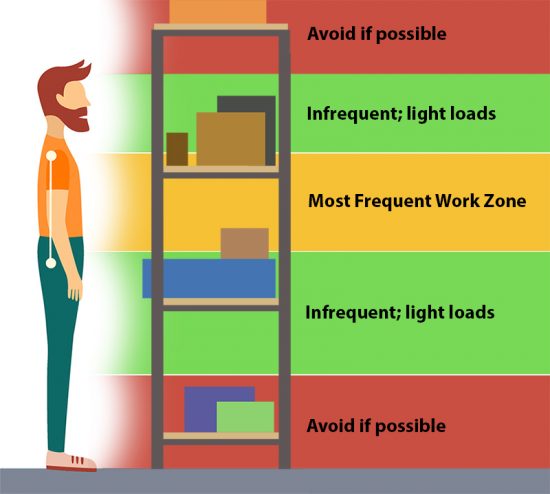

Ergonomic Warehouse actively ensuring workplace safety in the warehouse area. Typically it involves repetitive actions like lifting, bending, and reaching for objects. Therefore, it makes the workers susceptible to muscle and bone injuries, commonly known as musculoskeletal disorders.

Read More : Most Common Used Anthropometric Tools in OHS Testing

Therefore, warehouse workers actively need to understand the concept of ergonomics or utilize tools that facilitate their tasks. Essentially, ergonomics involves actively designing facilities, work systems, and postures that actively minimize the risk of injury.

Then, What is The Most Important of Workplace Ergonomic Safety Tips for Warehouse Worker ?

1.Workflow Training

It sounds simple, but you need to involve occupational safety and health (OSH) experts in your company management to maintain your company’s productivity. This applies to manual workers or lift or forklift operators. The warehouse area becomes the busiest area, so marking each area, such as areas where manual workers are not allowed to pass and safety rails around vulnerable points in the pallet rack system, helps protect products, people, and the system itself.

2. Employee Understanding of Basic Lifting Techniques

OSH training is a company’s obligation to each of its employees. Starting with a basic understanding of lifting activities. For example, Workers use about 700 pounds of back muscle force when lifting a 25-pound box from the floor.

How can we minimize the force used? Workers need to understand the correct techniques for lifting objects.

Firstly, the correct way is to rely on the legs and avoid bending from the waist. Additionally, workers also need to keep their back straight without twisting the spine.

However, simple examples like this are sometimes still underestimated by workers and management. Consequently, this can lead to high levels of fatigue and decreased productivity.

3. Evaluate The Environmental and Workload Evaluation

When you feel you have followed all procedures and still encounter workplace accidents, you may question the following:

- Is the lighting too dim or sufficiently bright?

- Should I seek technical assistance when carrying this load?

- Does this type of item require special handling? (when dealing with chemicals)

- Are there any protruding or sharp parts?

- With this height, will it obstruct my view

4. Perform Anthropometric Measurements and Adjust the Work Area

Adjusting the work area and tools will be maximized if you conduct Anthropometric measurements. Anthropometric measurement is the measurement of human dimensions that you can do for each of your workers. This serves to measure the physical abilities of each worker and then adjust the layout of the work area. Additionally, it also serves to select tools that have been adapted to human body dimensions.

The tool used in conducting Anthropometric measurements is the Portable Anthropometry Complete Set Series (CSS). Portable Anthropometry is a measuring tool that can measure more than 100 dimensions of the human body from standing to sitting positions.

Portable Anthropometry, Ergonomic Measurement Tool For Testing Work Safety

Portable Anthropometry is an anthropometric measuring instrument that can measure more than 100 dimensions of the human body in a standing to sitting position. With the data generated by Portable Anthropometry, the industry can find out the work environment and supporting instruments that are suitable for the workload so that occupational health and safety can be achieved. The reason is that the application of Anthropometric data can be easily found, as is the case in the application of room and chair designs and work desks. Various sectors have also used Portable Anthropometry, ranging from the education sector, especially industrial engineering and health, the sports sector, the military to the aviation industry and space research.

Get The Most Common Used Anthropometric Tools

The most common used Anthropometric Tools are Anthropometry Chair and Portable Anthropometry. These instruments have used in all sectors, including Occupational Health Sector (OHS). Solo Abadi Indonesia fully supports the Government of Indonesia to create innovations in the application of Occupational Health and Safety (OHS) in various sectors in Indonesia.

Contact our admin for further consultation via WhatsApp and get more information via www.soloabadi.com