The textile industry is a manufacturing industry that processes fiber into yarn, which is then made into clothes and goods that we currently use. Until now, the textile industry is still the largest manufacturing industry. In addition, it is widely known that the textile industry has a very large role in absorbing a large number of workers.

As industrial tools develop in supporting the production process, feeder machines in making it easier for human power to produce more and more needs. The textile industry is one of the industries that use feeder machines in the production process. Why is that? Check out the following explanation.

Development of Textile Industry In Indonesia

Historically, the textile industry started from the cottage industry in 1929. This industry started from the weaving and knitting sector using The Textile Inrichting Bandung (TIB) Gethouw tool or Non-Machine Loom (ATBM) invented by Daalennoord in 1926. This machine can produce scarves, belts, long fabrics, and sarongs.

As technology advances rapidly, Non-Machine Looms (ATM) are being replaced by Machine Looms (ATM). The use of ATM is easier and more practical in the textile industry because everything is done by machines. In addition, ATM also serves to improve and improve the efficiency of more quality production processes. Until now the textile industry continues to experience significant developments following technological advances.

The Role of Feeder Machines in The Textile Industry

The feeder machine or called feeder machine serves to remove paper one by one. The feeder machine is one of the supporting machines in the production of fabric in the textile industry. The feeder machine helps in the punching process. The punching process is a machining process that applies an automatic system in the work of card perforation. This process starts from the card intake and card taking that will be used in making patterns.

Feeder machines help in removing cards one by one for the next pattern that has been formed can be used in the fabric manufacturing process. In the feeder machine, there is a loading stuck process, wherein this process can insert and issue pattern design cards to exit one by one automatically.

Feeder machines in the production process have advantages including:

- Saves time spending pattern card effectively and efficiently, because it is done using an automatic machine.

- Save human resources.

- Minimize errors in the production process.

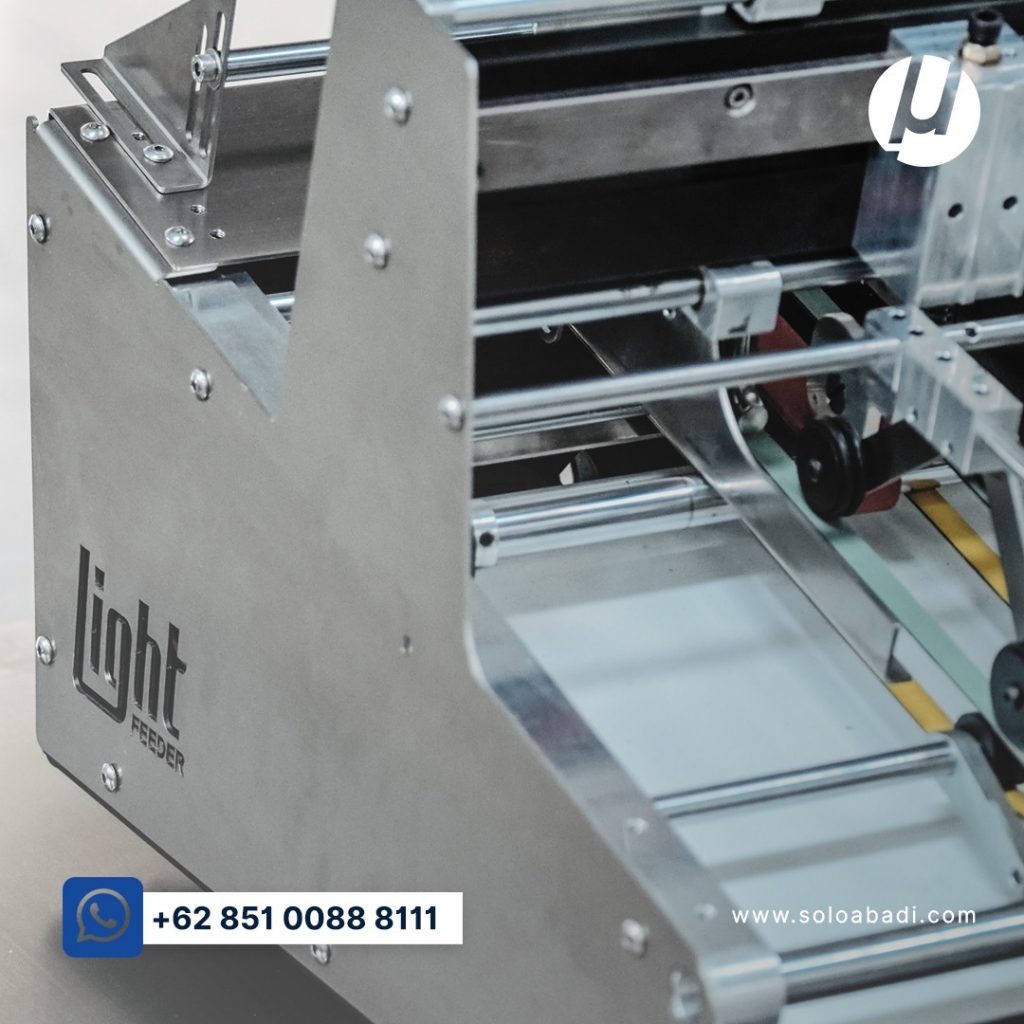

Feeder Machine Produced by PT Solo Abadi Indonesia

PT Solo Abadi Indonesia is a company engaged in the manufacturing industry. One of them is the Light Feeder Machine. This Light Feeder machine has several advantages including:

- Products are native to Indonesia because they are made from original Indonesian materials and materials.

- A simple and easy to operate machine model.

- The speed in the production process can be adjusted to the needs.

- Can be paired with other production machines as needed.

- The machine is easy to clean.

- Made of stainless steel material so that is anti-rust and strong.

- Quality products.

If your textile industry is interested in having this Solo Abadi Light Feeder Machine you can consult for FREE via WhatsApp or directly ASK FOR PRICE. You can also visit our social media on Instagram and YouTube to see other products from Solo Abadi. Solo Abadi, Creative Work Sincerely Serves.

Read also on an article on The Role of Light Feeder for The Beverage Industry.