In modern industry, ways to packing goods properly and correctly, ensuring product safety is still not given much attention. Packaging is an important part of the supply chain that determines how a product is viewed, received, and remains safe during distribution. Therefore, it is important to look at ways to packing goods properly and correctly so that they are safe and not easily damaged.

10 Ways to Pack Items Properly & Correctly in Accordance with SOPs!

To ensure product safety during shipping, here are ten ways to pack items properly:

1. Use Packaging That Suits Your Needs

For heavy or fragile items, be sure to choose sturdy cardboard boxes or containers with at least five layers. Successful packaging depends on good packaging.

2. Choose the Right Packaging Size

Make sure it is not too big or too small, as both can cause the goods to shift inside the packaging. The right size prevents damage inside.

3. Use Additional Protection

If your product needs bubble wrap, styrofoam, or foam padding, add them inside the packaging. Shock absorbers are very important for technical, electronic, and other products.

4. Protect the Edges and Corners of the Packaging

The edges and corners of the packaging are the most vulnerable or easily damaged parts. Therefore, you can use tape around the edges and corners of the packaging.

5. Utilize Empty Space by Filling It

To prevent items from moving when shaken and to avoid unwanted collisions or damage to the product, fill the empty space with shredded paper, sponge sheets, or packing peanuts.

6. Use the Right Tape

Ensure that the H-Tape technique is applied so that all sides are tightly sealed. Make sure there are no open joints or air gaps. Also, ensure that the size and material of the tape used are appropriate for its function.

7. Label for Handling

Attach stickers such as “Fragile” or “This Side Up,” as well as complete sender and recipient address information. This is useful so that when the product is shipped, the shipping/courier company can access this information.

8. Protect from Weather and Water

If the product is sensitive to temperature and humidity, use a protective plastic layer, silica gel, or dry wrap. This is useful to ensure that the product does not suffer damage or defects during shipping.

9. Meet Logistics Requirements

Ensure that the packaging meets shipping requirements, such as packaging type, maximum weight, etc. This can be anticipated by inquiring about the requirements with the shipping company in advance.

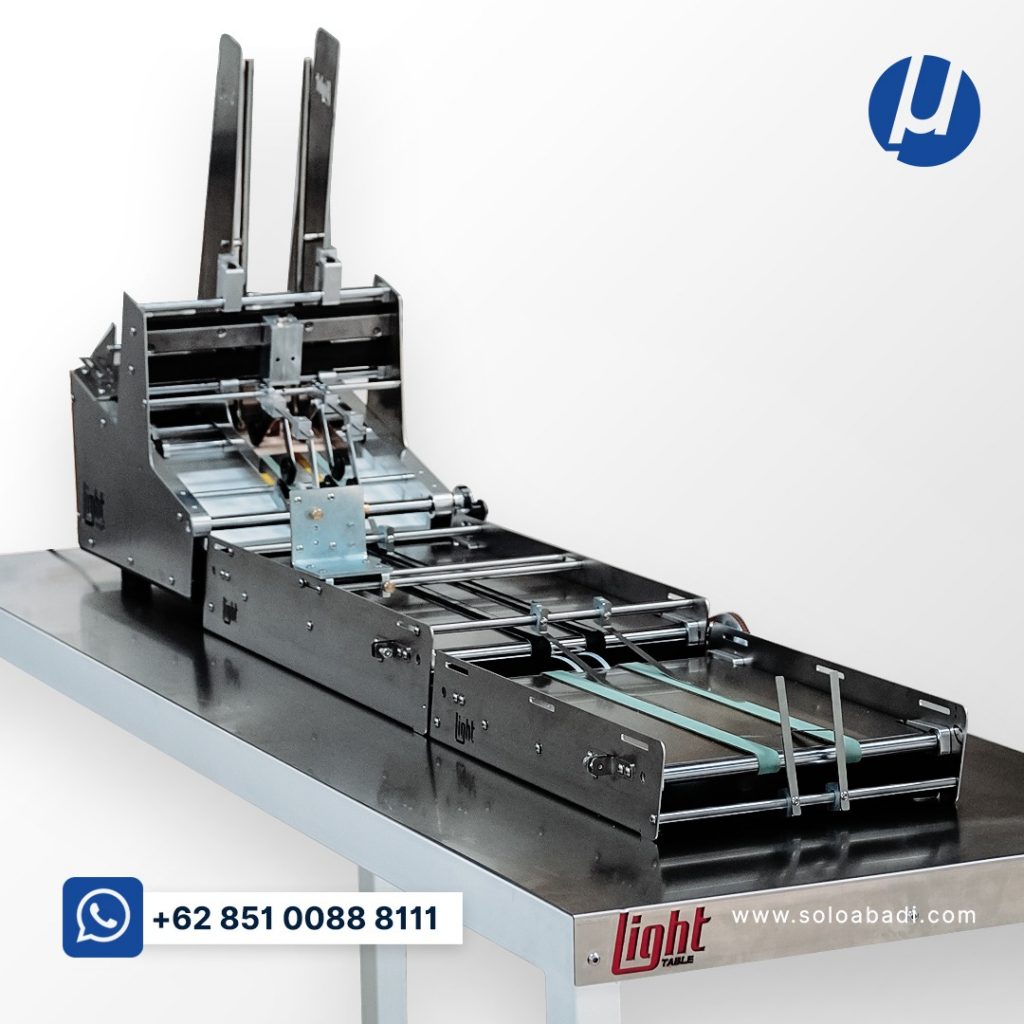

10. Use Automation Machines

Currently, many industries are switching to automation systems to make production processes more efficient and reduce production costs. An example of automation machines in the field of packing is the friction feeder machine, such as the Light Feeder from Solo Abadi.

Need a Feeder Machine to Simplify Your Production Process and Improve Your Packing Efficiency? We Are Ready to Help You!

What is a Light Feeder? A Light Feeder machine is a type of friction feeder that dispenses paper one sheet at a time. Light Feeder is the only feeder machine that is 100% made in Indonesia with various advantages, including:

- The only feeder machine made in Indonesia.

- Can be customized according to your needs, including speed and size.

- Made of stainless steel, making it rust-proof, strong, and durable.

- Can be used for various industries, such as printing, pharmaceuticals, food, and beauty.

What are you waiting for? Contact us now and get the machine of your dreams! You can find complete information on our website, including the Ask for Price feature for the best price quotes. Don’t forget to follow our Instagram for the latest updates. Contact us via WhatsApp or via our Email and Phone Number.

This article is writen by Hilarius Julian Satrio Abinowo, Manufacturing Design Student, Polytechnic ATMI Surakarta, 55th Class Batch.