The Ergonomic Requirements of Occupational Health and Safety takes a big role in creating work environments that are safe, efficient, and comfortable for employees, reducing the risk of injury and improving productivity. Ergonomics, the science of designing tasks and workspaces to fit the worker, plays a critical role in minimizing risks associated with repetitive movements, poor posture, and physical strain. This article explores the core ergonomic requirements in OHS and their importance based on scientific principles and research.

Why There Should Be Ergonomic Requirements of Occupational Health and Safety?

Ergonomics is vital in Occupational Health and Safety (OHS) because it helps prevent common work injuries, especially musculoskeletal disorders caused by repetitive movements and poor posture. Research shows that ergonomic adjustments, like arranging workstations to support natural body movements, can significantly reduce the risk of strain injuries, which are a major source of workplace-related health issues.

Besides injury prevention, ergonomics improves productivity and comfort at work. Studies find that employees in ergonomic environments experience less fatigue, focus better, and make fewer mistakes. When workstations and tools are designed to fit their needs, workers feel less distracted by discomfort, allowing them to work more efficiently, which also reduces company costs related to injury absences.

Finally, prioritizing ergonomics builds a strong safety culture. Regular assessments and ergonomic adjustments show workers that their well-being matters, boosting morale and job satisfaction. In this way, ergonomics not only keeps workers safe but also fosters a positive, efficient work environment.

So, What Are The Occupational Health and Safety Ergonomic Requirements?

1. Ergonomic Requirement of Workplace Layout and Design

A well-designed workspace can greatly reduce physical strain and enhance productivity. Ergonomic OHS guidelines advocate for workspaces that allow natural movements and minimize unnecessary reaching, bending, or twisting. For example, a workstation where frequently used items are within easy reach helps reduce the risk of musculoskeletal disorders (MSDs), which are one of the leading causes of workplace injury.

Scientific studies have shown that improper workplace layout can lead to repetitive strain injuries (RSIs), back pain, and other MSDs. By designing work areas according to ergonomic principles—such as the appropriate placement of monitors, adjustable desks, and proper chair height—organizations can significantly lower these risks.

2. Ergonomic Requirement of Posture and Positioning

Maintaining a neutral posture is a cornerstone of ergonomic safety. The neutral posture aligns the body in a position that minimizes stress on muscles, tendons, and bones. For instance, a neutral sitting posture involves a straight back, feet flat on the floor, and elbows close to the body at a 90-degree angle. When workers are encouraged to maintain good posture, they are less likely to develop chronic back pain and other MSDs.

According to OHS standards, ergonomic workspaces must accommodate adjustments that allow workers to achieve this ideal posture. For seated tasks, chairs should be adjustable to support the natural curvature of the spine. Standing workstations, on the other hand, should include anti-fatigue mats to reduce pressure on the legs and lower back.

3. Ergonomic Requirement of Tool and Equipment Design

Tools and equipment should be ergonomically designed to reduce excessive force, awkward positioning, and repetitive strain. Hand tools, for example, should fit the worker’s hand size and shape, be lightweight, and allow a comfortable grip to minimize strain. The use of poorly designed tools has been scientifically linked to increased risk of carpal tunnel syndrome, tendinitis, and other hand and wrist conditions.

Ergonomically designed tools reduce the risk of injury by accommodating natural hand and wrist movements. For instance, power tools that allow workers to keep a neutral wrist position, rather than forcing them into awkward angles, help prevent joint and tendon injuries. This aligns with OHS standards that aim to protect workers from cumulative trauma.

4. Ergonomic Requirement of Repetitive Motion and Task Variation

Repetitive motions, such as typing or assembling parts, can lead to RSIs when not managed properly. Ergonomic OHS guidelines emphasize the importance of task variety and regular breaks to reduce the risk of repetitive motion injuries. For instance, jobs requiring continuous data entry or assembly should allow for frequent breaks or rotation between tasks to prevent strain from repetitive actions.

Research confirms that continuous repetitive tasks without breaks lead to faster muscle fatigue and higher rates of RSIs. OHS ergonomic requirements thus advocate for “micro-breaks” or task rotation to promote muscle recovery, improve circulation, and lower the risk of injury.

5. Ergonomic Requirement of Lighting and Vision Ergonomics

Proper lighting is an essential ergonomic requirement, as poor lighting can lead to eye strain, headaches, and reduced concentration. Adequate lighting should reduce glare and shadows, allowing workers to see clearly without straining their eyes. In work that requires computer use, OHS ergonomic standards recommend adjustable monitors and glare-reducing screens to prevent visual discomfort.

Scientific evidence suggests that eye strain and poor lighting are linked to increased fatigue, which can lower productivity and lead to long-term vision problems. OHS guidelines recommend an optimal mix of natural and artificial lighting, along with computer monitor adjustments (such as screen height and brightness) to create a visually ergonomic workspace.

6. Ergonomic Requirement of Temperature and Ventilation Control

Environmental factors, like temperature and air quality, significantly impact comfort and productivity. Ergonomic OHS guidelines recommend maintaining a moderate temperature (around 20-24°C) and good air quality in the workplace. Scientific studies show that extreme temperatures (too hot or too cold) can lead to discomfort, fatigue, and reduced focus, increasing the likelihood of errors and injuries.

Proper ventilation ensures fresh airflow, which can reduce fatigue and enhance cognitive function. Maintaining a comfortable thermal environment and good ventilation is a key ergonomic requirement that supports worker health and productivity.

7. Ergonomic Requirement of Training and Awareness

Training is a foundational aspect of OHS ergonomic standards, as even the best-designed workspaces require workers to use proper techniques and equipment. Ergonomic training helps employees understand correct body mechanics, the importance of posture, and safe practices to prevent injury. This awareness reduces the likelihood of MSDs and reinforces a culture of safety within the organization.

Studies on workplace safety highlight that trained employees are better at identifying potential ergonomic risks and can make adjustments to avoid strain. Training also empowers workers to advocate for ergonomic changes, fostering a proactive approach to workplace safety.

8. Regular Ergonomic Assessments and Adjustments

Finally, OHS standards emphasize the importance of ongoing ergonomic assessments. As work processes and technologies evolve, regular evaluations help ensure that the workplace remains ergonomically sound. Adjustments can be made based on feedback from employees and changing job requirements, addressing ergonomic risks proactively.

Research shows that workplaces with regular ergonomic assessments experience lower rates of workplace injuries and associated costs. These assessments, conducted by ergonomics specialists, allow organizations to continuously improve safety conditions, ensuring that ergonomic needs are met over time.

Ergonomic Assessment Tool for Ergonomic Requirement

Ergonomic requirements are essential to occupational health and safety, reducing physical strain, preventing injuries, and enhancing overall productivity. By focusing on factors like posture, workspace layout, tool design, and environmental conditions, OHS standards support worker well-being and minimize ergonomic risks. Regular training and assessments further reinforce a safe and ergonomic workplace, allowing organizations to maintain a culture of health, safety, and efficiency. Through these scientifically supported practices, ergonomics contributes significantly to the sustainable success and well-being of workers and employers alike.

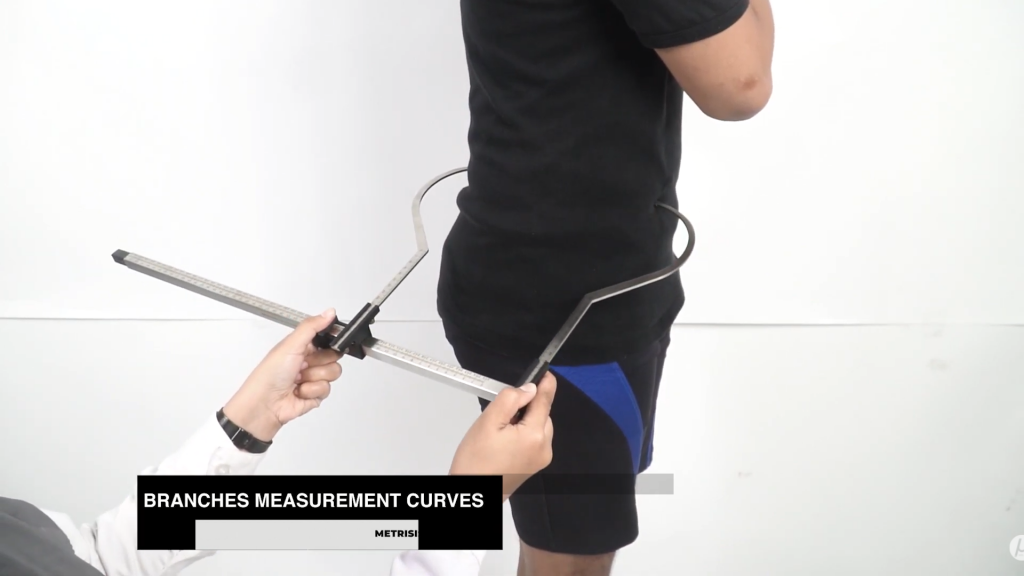

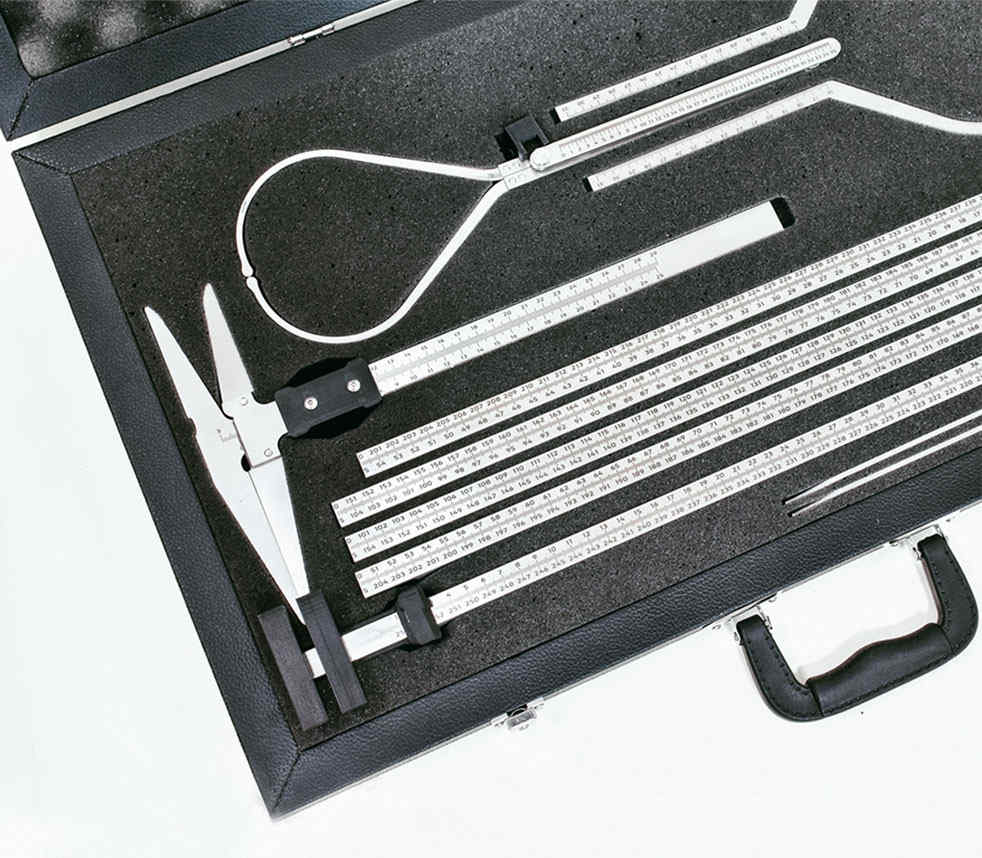

Portable Anthropometry is an anthropometric measurement tool capable of measuring up to 100 human body dimensions. This instrument allowed you to measure the human body so that you will achieve the Occupational Health and Safety.

Find Portable Anthropometry Here

Both of these tools have been used in various institutions, both domestically and internationally. These institutions focus on various scientific fields, including education, government agencies, the military, architecture, and even forensic science.

For further information regarding these instruments please contact us through email at admin@soloabadi.com and WhatsApp on 08510888111.