What are parameters in the machining process? Parameter is a variable that becomes a reference or rule in the operation of a machine. When carrying out any kind of machining process, the selection of the right parameters is something that cannot be ignored. The parameters used will also affect production results, processing time, durability of machines and cutting tools and even worker safety. These things, of course, will ultimately be related to the benefits obtained by the industry.

Parameters in CNC Machining

After knowing what parameters are and why they are important, let’s get to know what parameters are used in CNC machining.

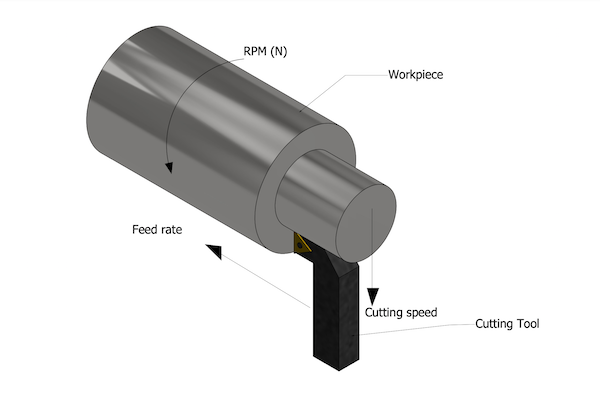

1. Cutting Speed

Cutting Speed or commonly referred to as CS alone is the ability of a cutting tool to nail the cutting in meters per minute. To determine the cutting speed we use the formula.

Cs = ᴨ x d x n

Where :

- ᴨ = constant 3.14

- d = workpiece diameter

- n = Engine Rotation Speed

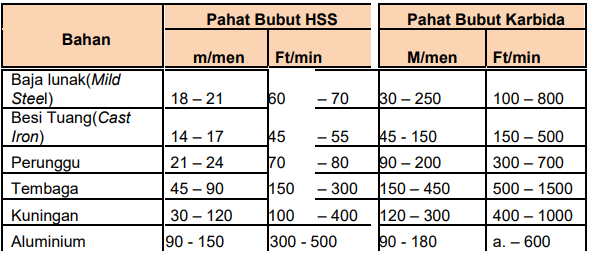

Now to determine the cutting speed of a material we no longer need to calculate it manually because the cutting speed of each material has been examined by experts and made one on a cutting speed table. Here are the contents of the table along with the type of cutting tools used.

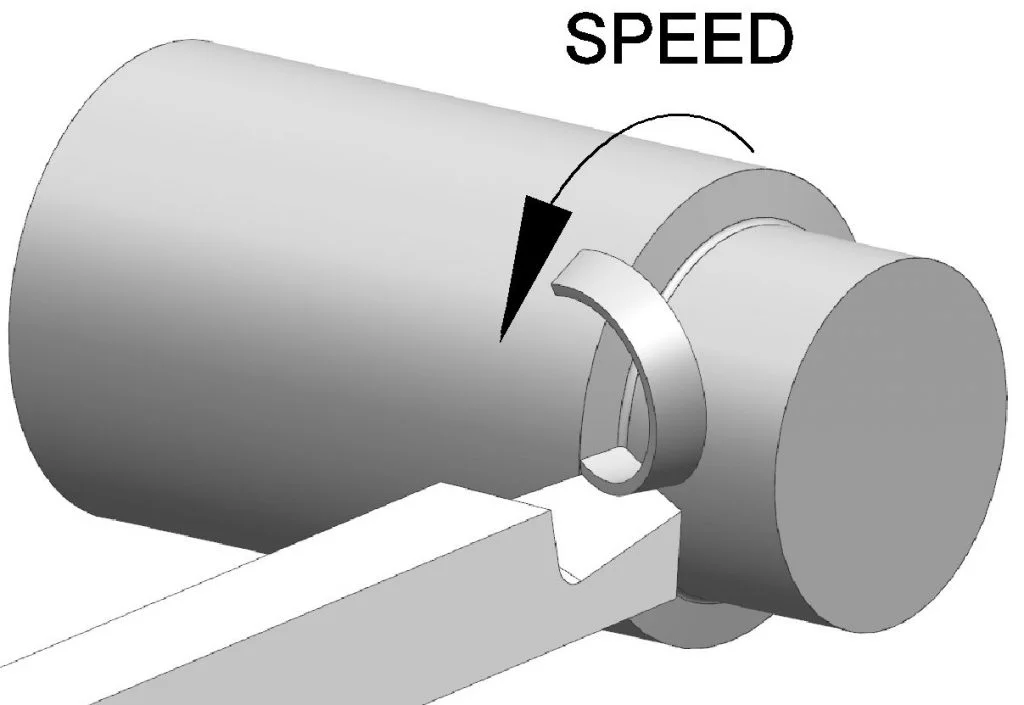

2. Spindle Speed

In the process of machining, spindle speed is the rotational speed of the spindle of the machine in certain units. In determining the spindle speed is greatly influenced by the cutting speed and diameter of the object. if the object is small in diameter, the spindle speed is higher, and vice versa. The formula for finding this Spindle Speed is:

n =Cs x 1000π x d

Where:

- ᴨ = komstanta 3.14

- d = workpiece diameter

- Cs = Cutting Speed

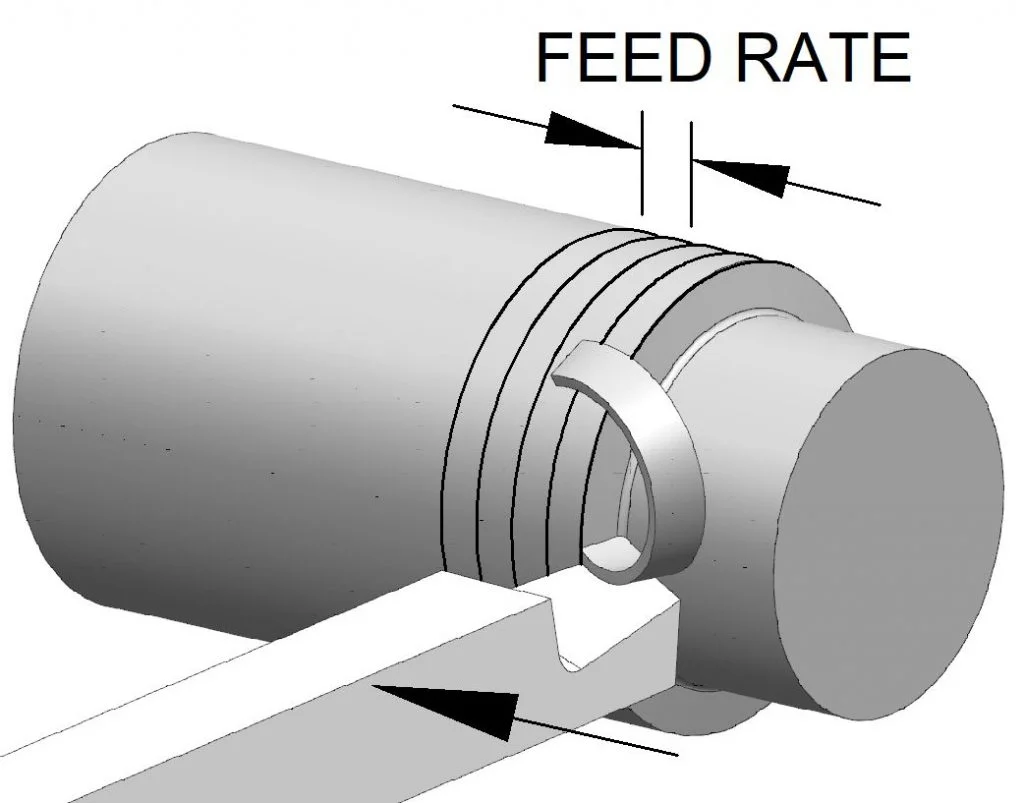

3. Usage Speed (Feed)

Feeding speed can be interpreted as the distance traveled by the cutting tool of each workpiece once rotated. Feeding speed is influenced by the hardness of the material, the type of cutting tool, the depth of feeding and also the ability of the machine. In the machining process, usually the greater the cutting speed, the resulting object also has a rough surface. Meanwhile, if the cutting speed is lower, the resulting object has a smooth surface. The formula for calculating the cutting speed will be described below.

F = f x n

Where:

- n= Spindle Speed

- f= Tool shift in mm/turn (see table)

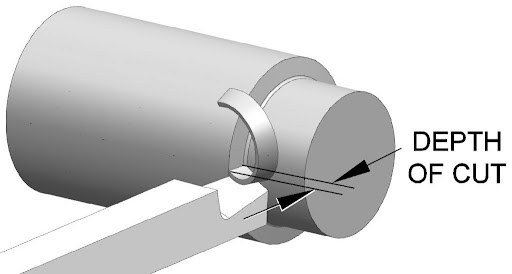

4. Depth of Cut

Depth Of Cut or depth of feeding is the thickness of the part of the workpiece that is removed at one feeding process. The selection of the appropriate depth of cut is very influential for the durability of the tool used. Depths of cut that are too high can cause the tool to break when used to cut the workpiece. The selection of depth of cut is not a special standard but is still selected based on the ability of the tool used and the type of material carried out by the machining process, usually as deep as 0.5-2 mm.

Solo Abadi Experienced in Producing High Precision Parts

In the processing of products that require high precision, parameters are vital and should not be underestimated so that production results can meet consumer satisfaction standards. At Solo Abadi we serve precision parts manufacturing services with guaranteed quality. Our experience in processing precision parts is unquestionable. In addition, we also offer special product machine manufacturing services. If you are interested please contact our WhatsApp number or visit our website for more information.

Read More: Getting to Know the Codes in CNC Machine Programming Languages