The 4.0 industrial revolution has changed all sides of life, even in manufacturing. Where in this field the changes are very visible that previously the work done by humans is now replaced by the existence of advanced machines in the production process.

One of the manufacturing fields that use machinery in the production process is the cosmetic industry. The cosmetic industry is an industry that is growing rapidly today to the interest of many people, especially women who are the main consumers of cosmetic products.

In the process of cosmetic production, the technology of making it becomes very important. Because the production process in this industry uses automatic that make it easier for humans to produce in large quantities. One of the supporting machines in the cosmetic industry is a feeder machine or called a feeder machine. How are feeder machines applied in this industry? Check it out in the following explanation.

Getting to Know the Cosmetic Industry: From Its Products to Its Manufacturing Technology

The cosmetic industry is an industry that produces cosmetic goods for use on human skin. The average consumer in this industry is a woman. Meanwhile, cosmetics are interpreted as ingredients that are ready to be used on parts of the body incluiding the epidermis, hair, nails, lips, outer genital organs, teeth, and oral cavity. The function of the use of cosmetics on the body is to cleanse, add attractiviness, change appearance, protect to be in good condition, improve body odor but not to cure or treat diseases.

Cosmetic products are divided into three classifications, namely:

- Cosmetic skincare: cream, facial cleansing foam, lotion, massage cream, moisturizing lotion.

- Cosmetic makeup: foundation, powder, lipstick, blusher, eyeshadow, eyeliner, nail polish, and nail polish cleanser.

- Cosmetic bodies: solid-liquid bath soap, toiletries, sunscreen, sun oil, deodorant spray-stick-roll-on, bleaching, depilatory, and insect repellent.

The process of making cosmetics includes 5 stages, nemely:

- Mixing: the process of mixing processed materials into one in a large tank to dissolve, emulsify, and cool those materials.

- Pumping: the process of pulling fluid or cavity, then pressing it out on the other side to be able to change the emulsion and compress the air.

- Heat transfer: the process of raw materials is heated and cooled in a large tank with hot steam.

- Filtration: the process for purifying leiding water and purifying raw materials, as well as filtering liquids containing solid materials to be separated.

- Filling: the process of filling the finished product liquid into the packaging.

In the cosmetic industry the tools used include:

- Mixing/emulsification tanks: mixing or emulsifying tanks of raw materials in cosmetics.

- Dispersing/grinding mills: grinding tools or grinders to form a thin layer of certain raw materials to be converted to uniform raw materials, to produce products that are homogeneous and free of clumps.

- Homogenizer: a device used to form an emulsion to stir the production material at high speed to obtain bubbles.

- Filling equipment: a tool used to pump products after production by filling, folding, and clamping the lid and moving the necessary stamps.

Application of Feeder Machines in The Cosmetic Industry

Feeder machines in the cosmetic industry are applied in helping the packaging process. This process is in the final stages of production, where packaging requires a container that explains the production code, accuracy, and appearance of the packaging.

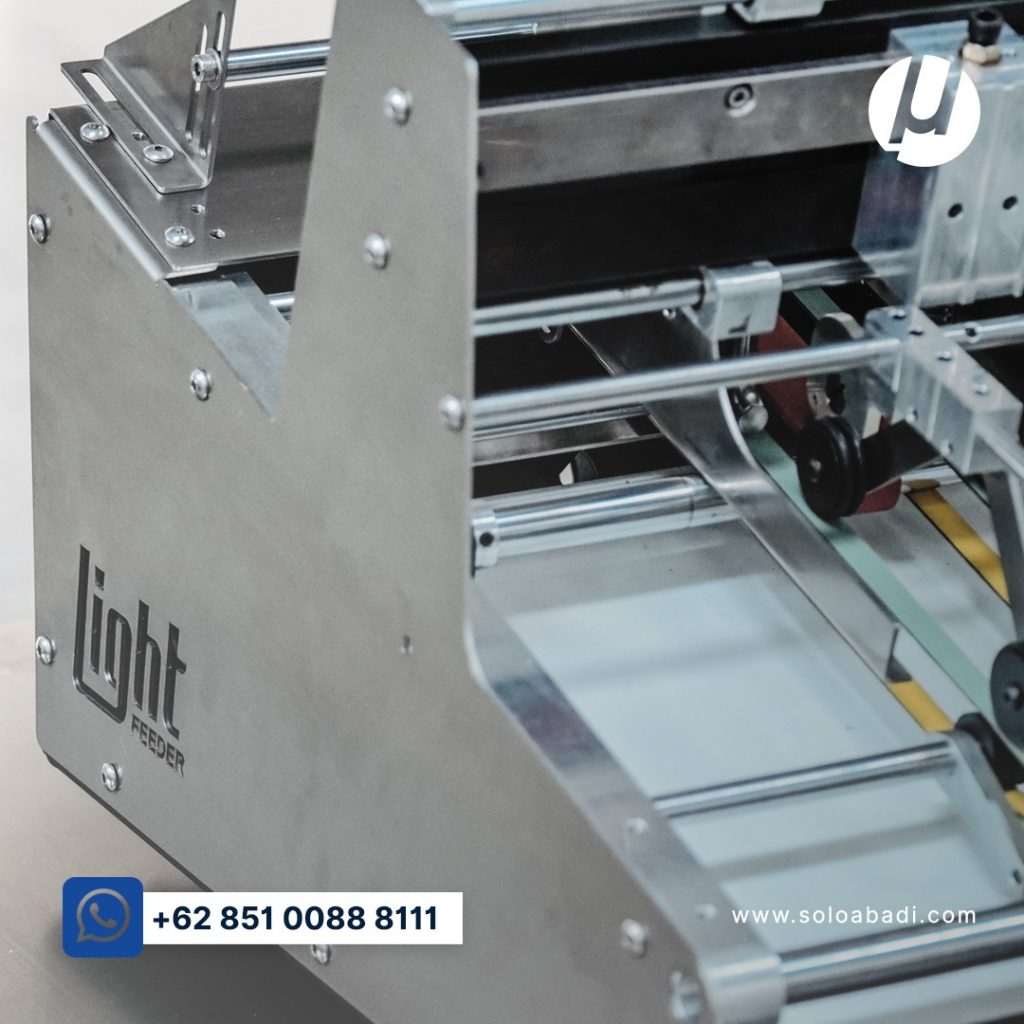

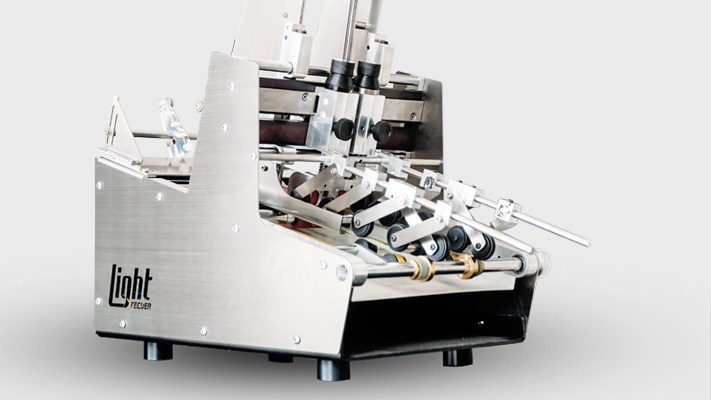

A feeder machine is a machine that is useful to remove paper one by one. This machine is a support in the packaging process to remove packaged products one by one automatically through the loading stuck process.

Feeder machines help minimize errors in the packaging process and save time packing quickly. In addition, it saves human resources effectively because it is worked by machines that can be set the speed rate in packaging.

Sell Feeder Machines, Local Products of Solo Abadi Production

PT Solo Abadi Indonesia is a manufacturing industry that produces feeder machines with its brand name is Light Feeder. PT Solo Abadi Indonesia is the only industry that produces feeder machines in Indonesia. Some of the advantages of PT Solo Abadi Indonesia’s feeder machine:

- Local products native to Indonesia, from materials and materials to assembly area in the country.

- The machine it easy to operate at a speed that can be adjusted to the needs.

- Adjustable machine, because it can be connected with other machines such as labeling machines, folding, inject printing, etc. according to needs.

- The machines is easy to clean.

- Friendly and lightweight machines maintenance for long-term use of the machine.

- The machine is made of stainless steel material so it is strong and anti-rust.

- The price is very reasonable with a very quality product.

For cosmetic industry companies you need this Light Feeder Machine, just visit the SOLO ABADI website or want to see product further can be directly through WhatsApp or direct message our social media on Instagram. You can also directly ASK FOR PRICE to order this product. SOLO ABADI, CREATIVE WORK SINCERELY SERVING.

You can also read the next article The Role of Light Feeder For The Beverage Industry.